Painting Production Line

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-08-15 Origin: Site

Automotive manufacturers achieve higher coating quality and reduce paint waste by implementing these smart systems, ultimately boosting automotive coating efficiency across production lines.

Smart painting production lines use robots, sensors, and AI. These tools help paint cars faster. They also make the paint job look better.

Automation and real-time data help use less paint. This lowers costs and keeps the coating process the same each time.

Predictive maintenance uses AI to stop machines from breaking. This saves time and money for the company.

Upstream and downstream equipment work well together. This helps the production flow and makes products better.

Training workers is important for smart coating technologies. Solving technical problems is also very important for success.

Industry 4.0 has changed how cars get painted. Machines, sensors, and software now work together in smart factories. These factories use computers to make virtual models of the painting process. This helps car makers test and improve things before changing them in real life. Digital twin technology finds slow spots and helps speed up work without stopping production. IoT sensors give live data about temperature, humidity, and machine health. This keeps coating quality steady.

Digital factory tools like AI cameras and machine learning spot surface problems like runs or rough spots. Automated root cause analysis finds issues fast, like blocked nozzles, and helps fix them quickly. These tools help make the finish better and lower repainting costs.

Car makers such as BMW use smart automation with smartwatches and robots for painting jobs. The table below shows main Industry 4.0 technologies used in car painting:

Industry 4.0 Component | Description | Automotive Coating Production Example |

|---|---|---|

Internet of Things (IoT) | Machines with sensors send live data for checking and studying. | Sensors check machine health and painting process details. |

Smart Factories | Factories use cloud, blockchain, and smart maintenance. | BMW’s Regensburg plant uses smartwatches and robots for painting. |

Cyber-physical Systems | Machines with sensors connect to the internet for remote checks and control. | Machines get checked from far away to cut down on stoppages. |

Artificial Intelligence (AI) | AI and machine learning study data to make production better, guess problems, and customize. | AI plans production and changes paint formulas. |

Robotics | Robots do exact, repeated jobs with people. | Robots sand and polish car bodies with cameras to find defects. |

Big Data Analytics | Looks at lots of data to find patterns and make things better. | Data helps cut waste and improve quality checks. |

Blockchain & Augmented Reality | Makes things safer, easier to track, and faster to fix. | AR drawings help repairs go faster; blockchain keeps data safe. |

Smart automation and controls from brands like anjiacoating help car makers work faster and stop less. These systems let teams watch and study things in real time. This helps them make choices that boost efficiency and quality.

Automation is very important in car painting. Robots make sure paint goes on evenly and cuts down on mistakes and waste. High-tech robot spray systems can lower paint mistakes by half. Robots handle dangerous chemicals and fumes, making work safer and saving money on labor.

Kawasaki and other companies make robot arms that are safe from explosions and have many moving parts for painting cars. These robots are light and have open arms so paint tools can be close to the sprayer. Automatic spray guns and mixing systems work with robots for quick painting and color changes. The ProMix PD Positive Displacement System mixes paint near the gun, so color changes are faster and flushing waste drops by 80%.

Automation/Robotics Type | Description/Function |

|---|---|

Robotic Spray Painting Systems | High-tech spray tools put paint on evenly for a smooth finish. |

Automated Spray Guns & Mixing Systems | Work with robots for quick painting and mixing. |

ProMix PD Positive Displacement System | Mixes paint near the gun for faster color changes and less waste. |

ProMix 2KS and 3KS Meter-Based Systems | Mixes two or three kinds of paint, good for many colors and chemicals. |

Compatible Robots | Fanuc, Yaskawa Motoman, ABB, Kawasaki robots made for car painting. |

Applicator Options | Rotary Bell Applicators, Electrostatic Spray Guns, Air Spray Guns, and more. |

Benefits | Less waste (up to 30%), better quality, lower labor costs, safer work, and less VOC pollution. |

Car makers use advanced painting robots for bodies, bumpers, and wheels. These robots paint evenly and save time. Features like automatic tracking and rotary cup spraying help use paint better by up to 40%. AI quality control systems set spray angles and find problems right away, helping keep machines running and boosting speed. Robots work all the time without getting tired, so production goes faster and deadlines are easier to meet.

Artificial intelligence is now key for predictive maintenance in car painting. AI watches sensor data like shaking and temperature to spot problems before things break. Predictive analytics let AI plan fixes that cut down on stoppages and costs. AI quality control systems check for tiny flaws in real time, making parts more reliable.

Car makers use machine learning to find faults and guess how long machines will last. Methods like Q-learning, decision trees, and neural networks sort out problems and guess failures. Hybrid deep learning models stop shutdowns better than old ways. The table below shows how AI helps with predictive maintenance:

Aspect | Description |

|---|---|

AI Role in Predictive Maintenance | Uses smart computer programs to study sensor data, find odd things, guess failures, and plan fixes to cut downtime and costs. |

Sensor Data Types | Temperature, shaking, pressure, humidity collected by IoT devices for checking machines all the time. |

Maintenance Approach Shift | Moves from regular fixes to fixes based on real machine state, which is more flexible and exact. |

AI Enhancements | Handles data from thousands of sensors at once, finds patterns, looks at old and new data for better guesses, and suggests fixes based on past problems. |

Integration Technologies | Mixes AI with IoT, edge computing, and digital twins to test and improve fixes before doing them for real. |

Use Cases | Checks shaking to find machine problems, watches oil to guess when it needs changing, uses heat pictures to spot hot parts. |

Benefits | Cuts surprise stoppages, lowers fix costs, makes machines more reliable, and helps car makers work better, including painting lines. |

Car factories using AI predictive maintenance save 20% or more on fix costs and have up to 50% fewer surprise stoppages. For example, BMW’s Leipzig plant finds bearing problems three weeks early, so fixes happen during planned stops. Deloitte says AI predictive maintenance cuts fix costs by 25-30% and downtime by 35-45%, saving millions each year. These upgrades in car painting show how smart controls and automation help factories work faster, better, and with higher quality.

Smart automotive paint booths let people watch and control them from far away. Cloud tools like Accudraft LIVE help managers see how booths work right now. They can check hours used, what workers do, and how many things get painted. These systems plan repairs, send alerts, and can even order new parts by themselves. Operators use touchscreens to save and pick paint programs for each job. Real-time SCADA systems warn about problems before machines stop working. One car maker in Europe had 15% fewer paint mistakes and faster jobs after using SCADA. Remote checks and one place to control many booths make it simple to run lots of booths and save money.

Special control panels set pressure, heat, and booth settings by themselves. This means less work for people and easier fixing from far away, so things run better and break less.

New paint booths try to use less energy and make less pollution. Smart airflow with Variable Frequency Drives changes fan speed to fit each job, which saves power. Economy modes slow down air when booths are not being used. LED lights help workers see colors better and use less electricity. Heat recovery systems take heat from used air and use it again, cutting heating bills by up to 30%. Good filters and water-based paint help lower VOC emissions and make the air cleaner. Some booths, like HBC Energy-Saving Paint Booths, use closed loops to cut energy use by up to 96%. These things help shops follow rules, spend less, and keep workers safe.

Smart vents move air the best way and need less heating or cooling.

Automatic paint sprayers waste less paint and spray less outside the lines.

Smart controls watch and change air, heat, and wetness all the time.

Smart tools help every car get the same good paint job. Digital controls and IoT sensors keep heat, air, and light steady for a smooth finish. Automatic steps move from spraying to baking to cooling with care. Computer color matching and mixing machines stop mistakes and save paint. Digital checks in real time help match colors and mix paint well. Fixes and schedules happen on their own, so machines work longer and paint jobs look the same. In big car factories, these tools give the exact results needed for perfect paint.

Feature | Benefit |

|---|---|

Digital Controls & IoT Sensors | Better paint jobs, fewer mistakes |

Robotic Spray Arms | Even painting, more cars painted |

Environmental Controls | Same finish every time, less fixing needed |

Predictive Maintenance | Fewer stops, more even paint |

Brands like (Anjia Coating) make spray booths with these smart tools, so car makers get great paint jobs every time.

Upstream integration is very important for making coatings faster. In car factories, pre-treatment and material handling systems connect with the main production line. Industry 4.0 tools like IoT and big data analytics help these steps share data right away. This connection lets factories use resources better, have less downtime, and make better products.

Material handling systems use conveyors and automated transporters. PLC and SCADA controls link each step together. This smooth connection keeps materials moving from pre-treatment to coating. It helps stop delays and makes teamwork better. Special powder coating systems combine handling and pre-treatment steps. This means faster changes and less waste. Automation makes sure every product is high quality, no matter how many or what kind.

Nippon Paint’s plant in Plessis-Pâté, France is a good example. The company makes 3,000 tonnes of car paint every year. They had trouble joining logistics and production for big jobs. By adding an Automated Storage and Retrieval System and Mecalux Easy WMS software, they kept products moving and tracked raw materials in real time. The system made FIFO stock management better and sped up answers to requests for raw materials. Connecting with their ERP system helped the warehouse and production talk to each other. This put all operations in one place.

Aspect | Details |

|---|---|

Company | Nippon Paint, a global leader in automotive paint manufacturing |

Location | Plessis-Pâté, France |

Production Scale | 3,000 tonnes of automotive paint annually |

Solutions | AS/RS for pallets, Mecalux Easy WMS, adjustable pallet racking |

Benefits | Continuous flow, real-time traceability, error-free FIFO, fast response, ERP integration |

Smart upstream integration, with help from brands like (Anjia Coating), helps car makers keep high productivity and quality from the start.

Downstream integration means the steps after coating, like curing, checking, and packing. These steps must work together to make the coating process better. Engineers use oven simulations to improve heat transfer and curing. This lowers stress and bending, so products are better. Good curing also saves energy and makes curing faster.

Car factories use different curing systems for powder, paint, and sealant. Conveying systems and full process lines move products smoothly from one step to the next. Custom coating systems, like trickle, roll coat, and dip and bake, help factories meet special needs. Heating methods like convection, resistance, induction, and infrared help cure different products. Conveying choices, like pallet conveyors and robot loading, make cycle times shorter and keep materials moving.

Inspection tools, like chemical checks and measuring devices, watch coating quality at every step. These checks make sure every product meets tough rules before packing. Packing and logistics teams handle finished products and make sure they arrive safely and on time. This way, cycle times get shorter and customers are happier because coatings last and look good.

New advances show clear improvements in speed and quality. Platforms like Brighton Science’s BConnect measure surface readiness in real time. This replaces guessing with exact water contact angle checks and cloud analytics. Makers can find and fix surface problems early, so there are fewer mistakes and less waste. Clemco Industries’ automated blast systems use robot arms and recipe controls for repeatable surface prep. These systems make results more even, speed up changes, and help workers do more. Car factories now get faster work, better quality, and fewer mistakes.

Tip: Downstream integration makes sure every coated part is top quality before leaving the factory. This helps efficiency and keeps customers happy.

Data and process coordination are the backbone of smart car coating production. Modular IT systems and Manufacturing Execution Systems (MES) connect upstream and downstream equipment. This gives a clear view of the whole process. By joining MES with ERP, IIoT, SCADA, and PLC systems, factories break down data walls and sync information in real time. This helps with predictive maintenance, smart analytics, and better decisions for improvement.

On the plant floor, MES connects with PLCs and SCADA using OPC UA and MQTT. This lets workers watch and control every step, from raw materials to packing, right away. New tech like AI vision systems and digital twins help with quality checks and speed. IIoT sensor networks collect data like vibration, temperature, and power use. This data helps predictive maintenance models cut downtime.

Plant iT is a modular IT system with MES features that helps coordinate upstream and downstream steps. It has real-time monitoring tools for clear data at all stages. Key features include:

Overall Equipment Effectiveness (OEE) monitoring tracks machine and line use.

Energy management shows detailed power use.

Fault and consumption analyses find downtime causes and wasted materials.

Batch and product tracking gives full traceability.

Recipe management links to ERP for quick changes and better results.

Dashboards and online reports give managers instant stats on performance, energy, and faults. Connecting with ERP and lab systems helps manage materials and check quality. The system maps material flows, records real values, and checks quality rules. Tracking lets teams look at production steps both upstream and downstream. This helps stop mistakes and makes processes clearer.

Smart data and process coordination turn scattered info into useful ideas. This boosts car coating efficiency, helps predictive maintenance, and makes sure every product is high quality. Using real-time data and automation, car makers get more done and stay ahead in the market.

Smart painting production lines help car makers get better results. Machine learning models guess how hard coatings will be. This stops guessing and makes work faster. Engineers use these models to change electric potential and powder feed pressure. They also set nozzle distance to control coating thickness. Data helps make changes quickly and cuts down on mistakes.

AI-based processes give even coating quality and help work go faster.

Robots put paint on cars exactly, even on tricky shapes.

IoT sensors and feedback loops stop too much spray and keep thickness the same.

Digital twins and predictive analytics let teams test ideas before using them. This makes work more exact and saves paint.

With these new tools, companies like 安佳涂装 (Anjia Coating) help car makers get great finishes every time.

Car painting now uses smart filters and separators to save paint. These systems get back over 99% of paint resins and pigments. They clean and reuse paint bath water for rinsing. This means less paint is lost and water costs go down. Membrane filters keep cleaning baths free from oil and dirt. This cuts down on chemicals and almost stops dumping baths.

Aspect | Traditional Coating Technologies | Intelligent Coating Machine Systems (ICMS) |

|---|---|---|

Automation & Precision | People spray by hand; more waste happens. | Robots, AI, and sensors control spraying exactly. |

Material Utilization & Waste | Too much spray and spills waste paint. | Nozzles and flow control cut waste by 30-50%. Unused paint gets recycled. |

Quality Control | People check for mistakes after painting. | AI and cameras find problems right away and fix them. |

Cost Considerations | Cheaper at first but costs more for labor and waste. | Costs more at first but saves money later by cutting waste and labor. |

Industry Application | Used for many jobs. | Needed for jobs that want high quality and less waste. |

These changes help save money and protect the environment.

Smart painting lines help every step work together, from start to finish. Real-time data sharing lets teams find problems early and keep work moving. AI checks for defects right away, so fewer parts need fixing or replacing.

Automatic tracking makes sure every batch is good before shipping.

Predictive maintenance stops surprise breakdowns and keeps deliveries on time.

Digital tools help managers act fast when demand changes.

With these systems, car makers can send out better products faster and more often.

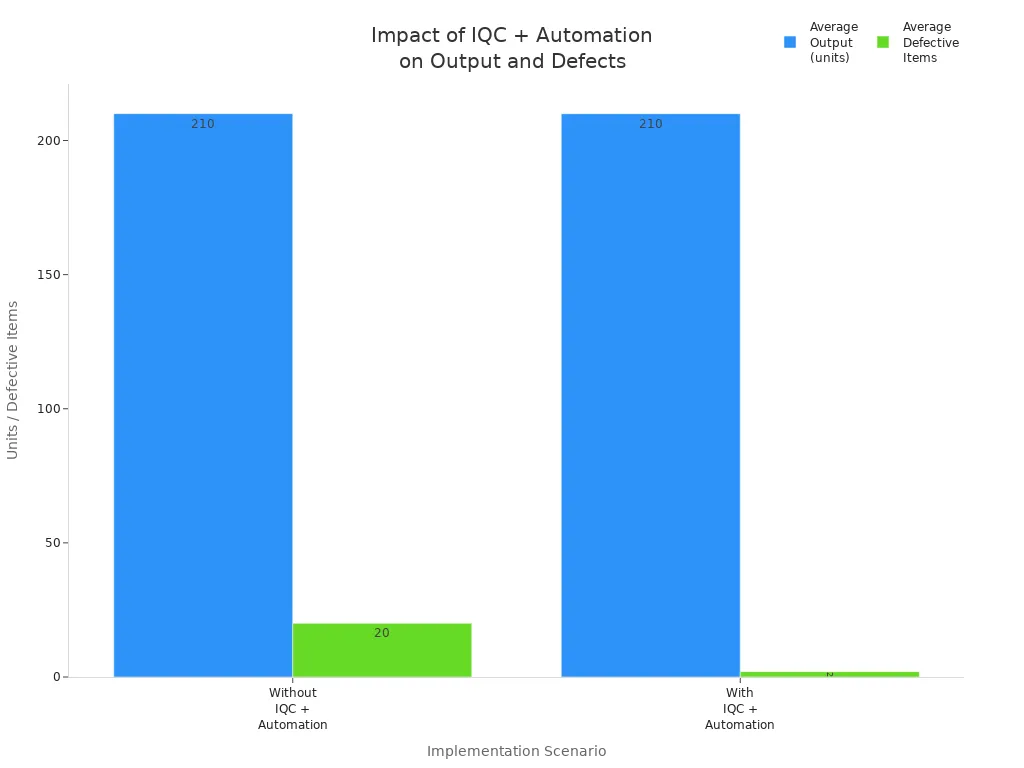

Car makers have seen great results with smart painting lines. Many companies use automation, in-line quality control, and digital systems now. These upgrades mean fewer mistakes and more cars made. A study compared old lines to new ones with IQC and automation. The number of bad items dropped from 20 to just 2. Output stayed the same at 210 units.

Metric | Without IQC + Automation | With IQC + Automation |

|---|---|---|

Average Output (units) | 210 | 210 |

Average Defective Items | 20 | 2 |

Productivity (defect-free ratio) | Lower | Significantly higher |

One top car maker cut rework by 37% using First Pass Yield. Another company made cycle time 22% faster, so products shipped quicker. Digital projects like HESCO made inspection time drop from two days to two hours. These changes stopped manual tracking and lowered mistakes. This helped efficiency and made customers happier.

Manufacturers learned important things from smart upgrades:

Sustainability and following rules are very important, especially in Europe.

AI painting and precision spray tech help save paint and protect nature.

Real-time data and IoT make quality checks and work better.

Machine learning helps fix machines before they break.

Cobots let people and robots work together and do more custom jobs.

Changing robots for local rules and needs helps them work well.

Car makers and robot companies working together bring new ideas.

Buying smart robots saves money and works well in new places.

New robot painting keeps companies ahead of others.

Brands like (Anjia Coating) help these changes, so car makers get good paint jobs and work better.

Car makers face many technical problems when adding smart systems. These problems can slow down work and make automation less helpful.

Different process control systems do not talk to each other well. This makes real-time data sharing slow and hard. Systems cannot react quickly to changes.

Many factories use old machines. These machines do not work with new smart technology. This makes it tough to use automation fully.

Some workers do not know how to use advanced control tools. This can cause mistakes and lower the quality of products.

Moving from lab tests to big factory use brings new issues. Factories must keep processes steady and repeatable as they get bigger.

Keeping quality high and processes stable at large scale is hard.

Using adaptive control and AI optimization is tricky. Problems include bad data, unclear algorithms, no standards, cyber risks, and high computer costs.

Makers like (Anjia Coating) help solve these problems. They build systems that work together and give training to teams.

Car makers help workers adapt by growing teams and teaching new skills. Many companies hire people for IT, operations, and data jobs. Training for leaders and staff helps everyone learn smart manufacturing skills. Some groups use outside classes to teach faster. Temporary workers help when skilled people are hard to find.

Outsourcing special jobs like tech and cybersecurity is now common. Many car makers let experts handle these tough tasks. Special teams lead smart manufacturing changes. Good communication keeps workers and customers updated about new ways of working. Centers of excellence help teams learn and share best practices.

Magna uses flexible systems with modular workstations. This lets workers handle different cars and production sizes easily. Strong in-house rules help teams adjust fast to new customer needs. Modular workstations and transport systems make work safe and efficient. Strict quality checks and certified labs keep surface quality high for all OEM needs.

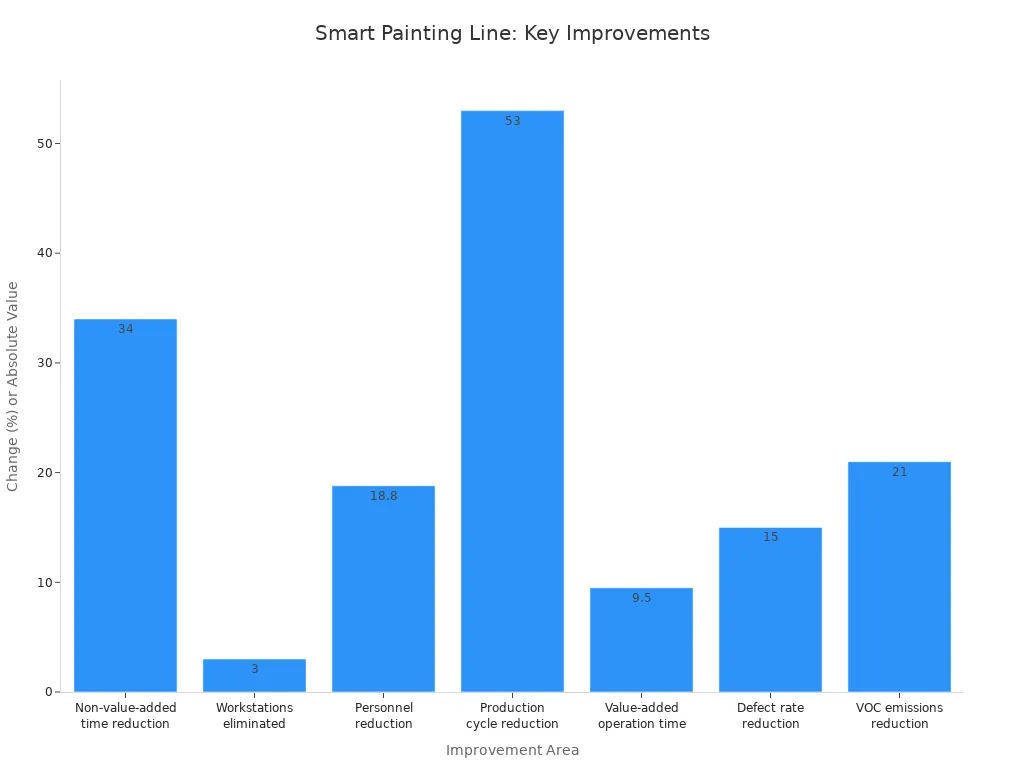

Smart systems and integrated equipment help car makers work better. These tools make automotive coating efficiency higher and keep companies strong. Manufacturers should use lean production and digital upgrades. They should also use intelligent technologies like robotic painting and IoT controls. Teams need to train workers and always look for ways to improve. The table below lists strategies that really work for better results. Leading brands such as (Anjia Coating) help with these upgrades.

Recommendation Area | Benefit Example |

|---|---|

Lean Production Management | 34 minutes less non-value time |

Digital Transformation | 53 minutes shorter production |

Intelligent Technologies | 15% fewer defects |

Environmental Compliance | VOC emissions cut to 9 mg/m³ |

Cost and Efficiency | Fewer operators, lower costs |

A smart painting production line uses robots and sensors. Computers help paint cars in factories. These systems make work faster and cut mistakes. Teams watch the process as it happens. They can fix problems right away.

Automation uses robots and digital controls for painting. These tools help put paint on evenly. Human errors go down and finishes look the same. Sensors check every step to keep quality high.

Predictive maintenance finds problems before machines break. AI looks at sensor data and warns workers early. This helps stop long breaks and saves money on repairs.

Upstream equipment gets car parts ready for painting. Downstream equipment cures, checks, and packs finished parts. When these systems connect, products move smoothly. Factories keep quality high.

Manufacturers can visit (Anjia Coating) for smart painting systems. The company gives automation, digital controls, and support for automotive coating efficiency.

content is empty!